Innovative self-developed specimen system

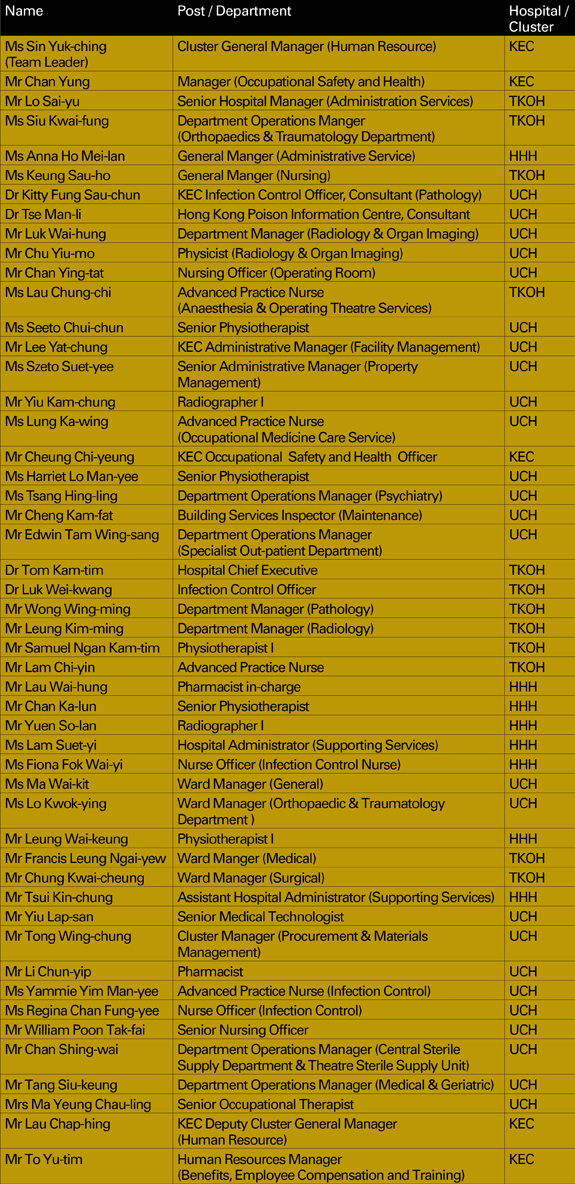

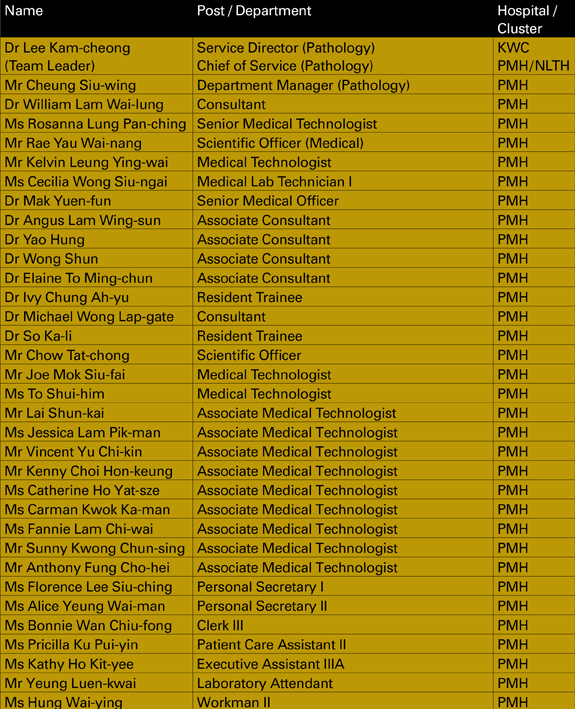

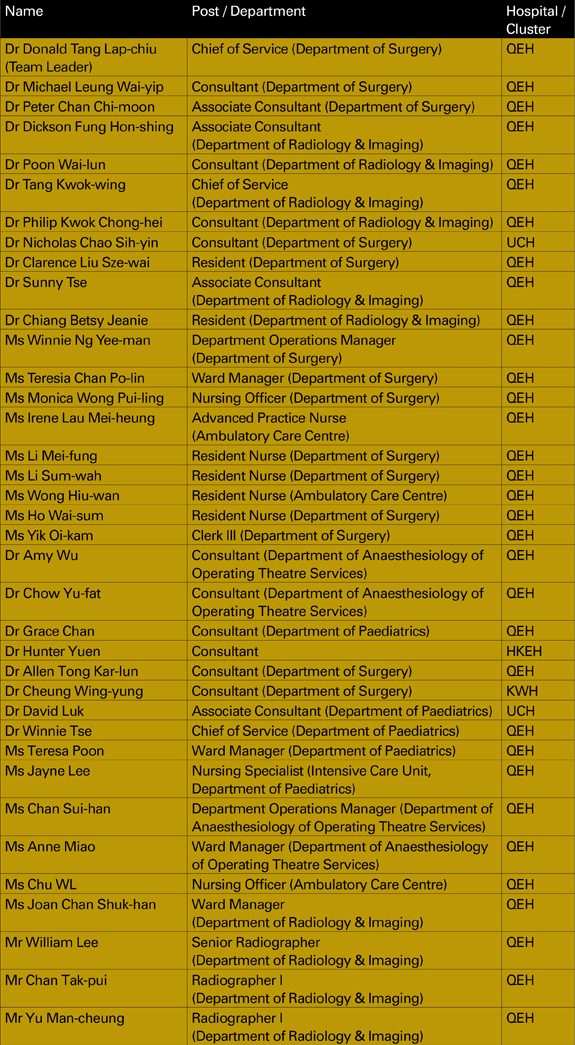

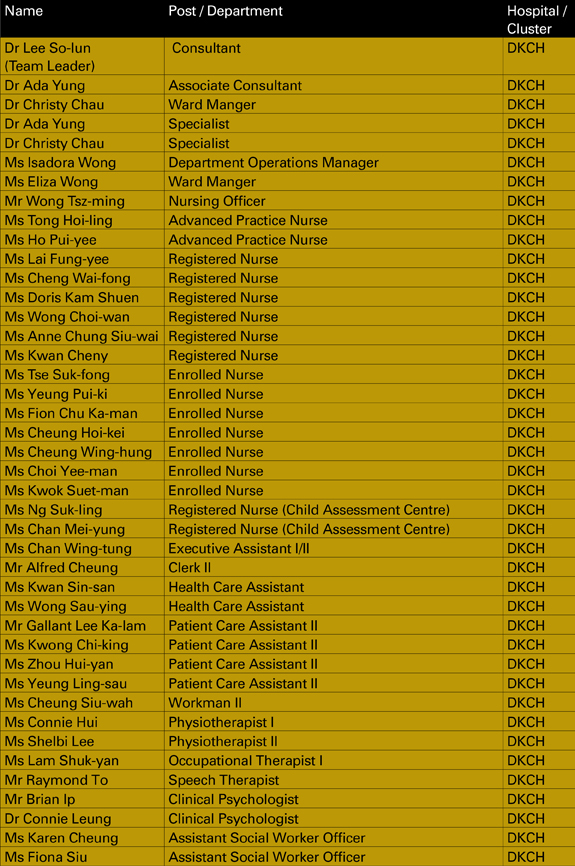

Princess Margaret Hospital Department of Pathology Specimen Assurance for Excellence (SAFE) Project Team

Princess Margaret Hospital (Kowloon West Cluster)

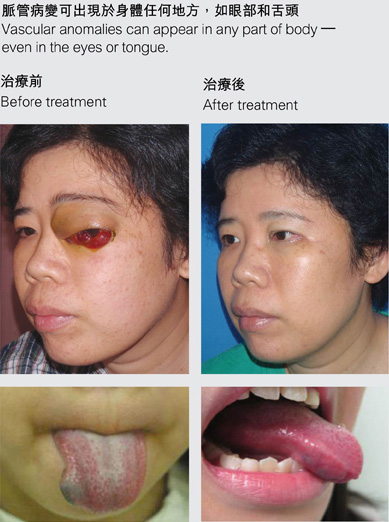

Specimen sampling, fixing, paraffin embedding, sectioning, staining – these are just some of the many small-but-crucial steps involved in processing the thousands of surgical specimens collected at Hospital Authority institutions each day. Every specimen is assigned a unique serial number that must be used to verify its identity at each stage of analysis. Any error in this identification process could have potentially serious consequences.

Since 2010, the Specimen Assurance for Excellence Project Team of the Department of Pathology at Princess Margaret Hospital (PMH) has devised an innovative system that has helped improve patient safety by reducing the risk of identification errors. Team leader Dr Lee Kam-cheong, who is also Chief of Service (Pathology) at PMH and Service Director (Pathology) of Kowloon West Cluster, developed and wrote the system programme according to the specific needs of hospitals in Hong Kong.

“Specimens and the resulting histology slides are like the trunk and leaves of a tree – the system I designed serves as the branches,” explains Dr Lee. “It uses 2D barcodes to link up the complex processing procedures for easy tracking and accurate identification.” The system is currently being used to safeguard identification for all surgical and cytology specimens.

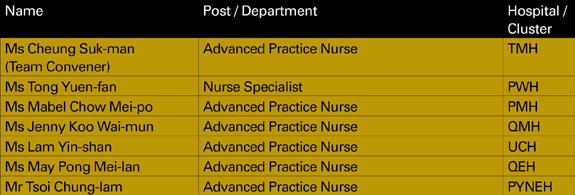

When a surgical specimen arrives at the laboratory, it will be assigned a unique 2D barcode, so will all subsequent samples derived from it in the downstream procedures. When laboratory staff are working with any samples during processing, they can efficiently verify the identity of each of them by scanning the barcodes to ensure it matches the parent specimen, rather than depending only on less reliable manual cross-check of the specimen’s serial number.

Dr Lee’s team included several features in the innovative system that makes it more flexible and efficient than similar systems used overseas. For example, if the number of specimen samples taken by pathologist in a patient’s specimen is changed, the system can automatically update and realign all the associated barcodes. Batching to improve efficiency is possible for certain operations. Also, for better resource management, the system records all consumables used in processing the specimens. Besides, the system has tracking functions so it is easy to know when, where, and at which stages of procedure a specimen is involving.

"Teamwork is so important that, without a shared vision and a sense of ownership by members, it is virtually impossible to develop and implement such a complex system within limited time and resource," Dr Lee adds.

In addition to PMH, the system is also in use at Yan Chai Hospital, Tuen Mun Hospital, Pok Oi Hospital, North District Hospital and Pamela Youde Nethersole Eastern Hospital, and will be gradually rolled out to all HA hospitals.

Each surgical specimen that arrives at the laboratory is given a unique 2D barcode label. |

|

|

Before undertaking any specimen analysis procedure, laboratory staff will scan the barcode on the specimen container and on the slide to ensure the identification information is the same. |

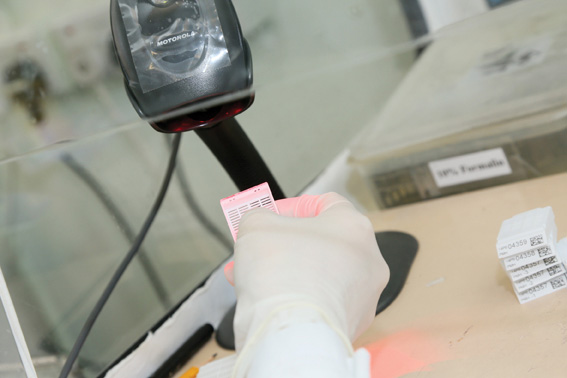

(From left) Reusable wooden paraffin blocks of the 1980s and the single-use plastic cassettes with handwritten code of the 1990s have been replaced by accurate and clear 2D barcodes. |